Introducing high-speed microscale 3D printing technology that can produce ultrafine particles of any shape at a rate of 1 million pieces per day

3D printed microparticles have a variety of uses, including the development of microelectronics and pharmaceuticals, and the manufacturing of complex parts, but they require precise control and manual processing, making mass production difficult until now. was. Researchers at Stanford University in the United States have announced a processing technology that automates the production of extremely fine microscale particles and can print up to 1 million particles per day.

Roll-to-roll, high-resolution 3D printing of shape-specific particles | Nature

High-speed microscale 3D printing | Stanford News

https://news.stanford.edu/2024/03/13/high-speed-microscale-3d-printing/

Researchers develop new 3D printing technique for the mass production of microscale particles - 3D Printing Industry

https://3dprintingindustry.com/news/researchers-develop-new-3d-printing-technique-for-the-mass-production-of-microscale-particles-229256/

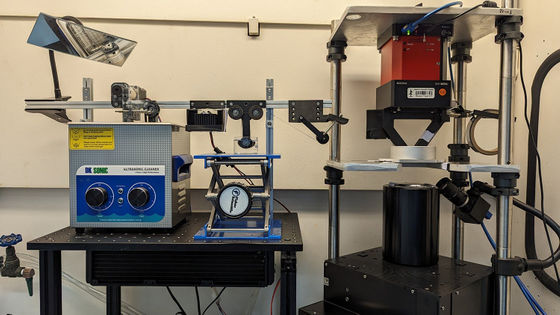

In 2015, Joseph M. DeSimone of Stanford University and his colleagues developed the Continuous Liquid Interface Manufacturing Method (CLIP) . Rather than curing the resin layer by layer as in traditional methods, this technology uses UV light projected through an oxygen-permeable film 'window' to continuously cure the resin, reducing the time required for 3D printing. is to be significantly shortened.

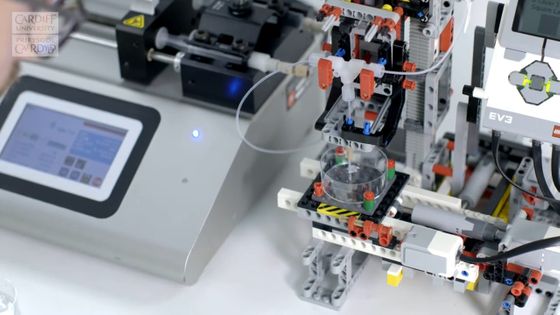

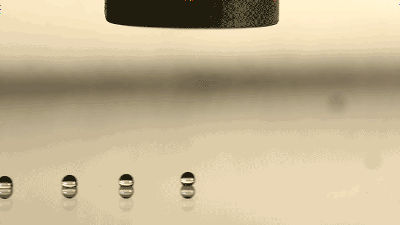

The research team has now developed a new ``roll-to-roll CLIP (r2rCLIP)'' that combines this CLIP with a production line method. This allows microscale models to be automatically 3D printed, cleaned, cured, and removed without the need for manual input, significantly increasing production speed.

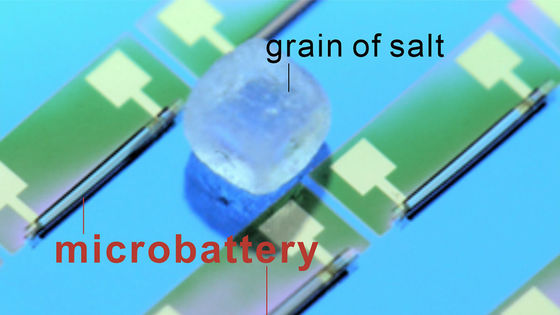

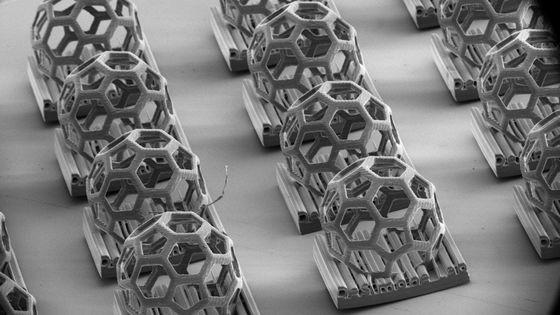

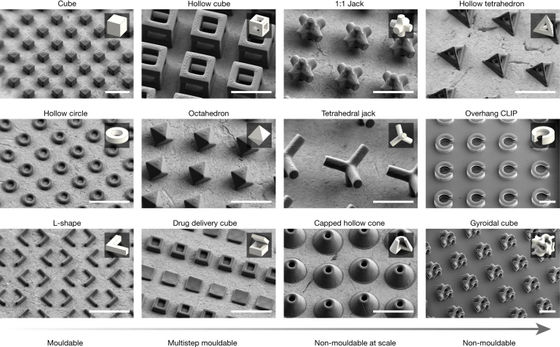

This approach makes it possible to 3D print materials with complex microscopic designs in large quantities, and is expected to have applications in biomedicine and advanced materials.

'We are now able to create more complex shapes at the microscopic scale at speeds not shown with traditional particle manufacturing,' said Jason Kronenfeld, a doctoral candidate in DeSimone's lab at Stanford University. It has become.”

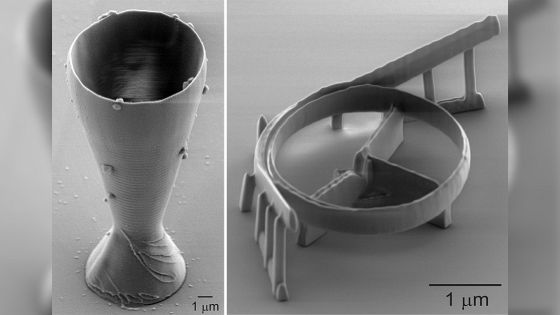

The newly developed 3D printer is capable of printing particles up to 200 micrometers with a feature resolution of 2 micrometers. To demonstrate the performance of this r2rCLIP, the research team 3D printed particles with various shapes, including the DeSimone Lab logo with

Conventional 3D printing technology involves a process of manually processing particles, which is time-consuming and labor-intensive. However, r2rCLIP's fully automated process allows it to 3D print up to 1 million particles per day.

The research team believes that with the high throughput of r2rCLIP, it will be possible to mass-produce a variety of particles, from microrobot parts to delivery containers for drug components.

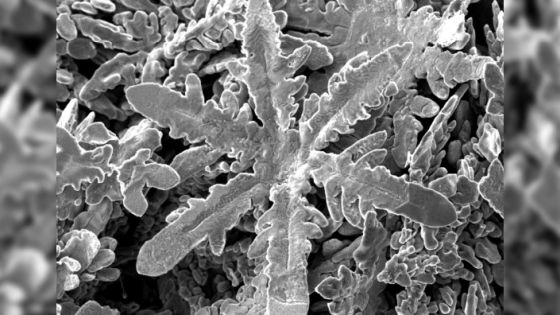

The research team has already begun experiments to 3D print hard ceramic particles for use in microelectronic manufacturing, and soft hydrogel particles for use in in-body drug delivery technology.

'Our approach has the advantage of being able to obtain high-resolution output while maintaining the manufacturing pace necessary to meet the particle production rates that experts consider essential for a variety of applications,' Kronenfeld said. It was something that stood out.”

Related Posts: